Efficient Heat Transfer Bulk Solid Plate Heat Exchanger Continuous

Operation Gas Solid Two Phase Flow

Overview:

Bulk solid heat exchanger is a highly efficient heat exchange

equipment designed for bulk materials such as particles and

powders. It adopts a unique gas-solid two-phase flow technology and

realizes efficient heat transfer through the countercurrent heat

exchange principle. Its modular design makes the equipment

installation and maintenance more convenient. At the same time, it

has the characteristics of high temperature resistance and high

wear resistance. It is suitable for material preheating, cooling

and other process links in many industries such as metallurgy,

chemical industry, and building materials. It can significantly

reduce energy consumption while ensuring large processing capacity.

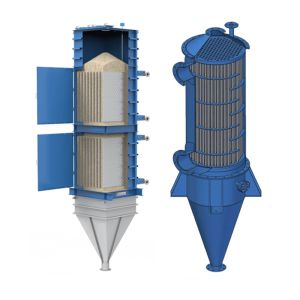

Product Image:

Brief Introduction:

Thickened plate design (2.0mm+2.0mm double pillow plate): withstands pressure of 4.0MPa (industry ≤2.5MPa), supports heat

transfer oil (400℃) and high-pressure steam (6MPa).

Anti-thermal deformation structure: The bulk solid heat exchanger adopts laser welding + corrugation

compensation technology, and the thermal stability under high

temperature conditions is improved by 40%.

Intelligent temperature control interlock: When the temperature exceeds the limit, the heat source is cut off

in 0.5 seconds, and the failure rate is <0.1 times/year.

Applicable scenarios: high-temperature catalyst, activated carbon particle cooling, and

high-temperature solid processing in refineries.

Advantages:

The bulk solid heat exchanger adopts a 2.0mm+2.0mm thickened double

pillow plate structure design (industry standard ≤1.5mm), and its

pressure resistance is 60% higher than that of conventional

products. It can stably carry 4.0MPa high-pressure steam or 400℃

high-temperature heat transfer oil. Its laser welding corrugation

compensation technology effectively disperses thermal stress under

extreme temperatures, and the thermal stability is improved by 40%,

ensuring continuous operation in high-load scenarios such as

refining and chemical industry. At the same time, it is equipped

with an intelligent temperature and pressure interlocking system,

which cuts off the heat source and starts safe discharge within 0.5

seconds when the pressure/temperature exceeds the limit. The annual

failure rate is close to zero, providing an integrated heat

exchange solution with extreme pressure resistance, thermal change

resistance and zero downtime for the treatment of high-risk media

such as high-temperature asphalt and high-pressure reaction liquid.

Applcation:

(1) Fertilizers – Urea, Ammonium Nitrate, NPK.

(2) Chemicals – Ammonium Sulphate, Soda Ash, Calcium Chloride.

(3) Plastics – Polyethylene, Nylon, PET Pellets, Polypropylene.

(4) Detergents and Phosphates.

(5) Food Products – Sugar, Salt, Seeds.

(6) Minerals – Sand, Resin coated Sand, Coals, Iron Carbide, Iron

Ore.

(7) High temperature Materials – Catalyst, Activated Carbon.

(8) Bio Solids Granules.

R&D and Production:

Ruiding has established the jiangsu province clean incineration

resource engineering technology center and the key laboratory of

the JICUI-Ruidings joint innovation center.

This laboratory is equipped with advanced detection equipment such as

ICP inductively coupled plasma emission spectrometry, atomic

absorption spectrophotometry, atomic fluorescence

spectrophotometry, high-temperature combustion ion chromatography

analyzer, high-temperature combustion rate analyzer, and rapid

equilibrium flash point tester. it possesses capabilities for heavy

metal analysis, elemental analysis, off-gas calorific value

analysis, ash melting point detection, incineration boiler water

quality testing, sewage analysis, and volatile waste analysis, etc.

Related Products:

Main Clients:

Company Introduction:

Ruiding is expertized in the engineering, fabrication,

construction, commissioning service of industrial waste combustion

treatment system including thermal oxidizer (also referred to as

incinerator), heat recovery system (boiler), pressurized vessel,

flue gas treatment system (DeSOX, DeNOx) and plate heat exchanger,

etc.

Ruiding has been authorized with the Environmental Protection

Engineering Class 2 (waste gas, waste liquid, waste solid

treatment) EPC certificate, ASME Certificate, Class A boiler

manufacturing license, Class A boiler installation and Revamping &

Maintenance certificate, A2 designing and manufacturing certificate

for press vessel, GC1, GC2 press pipeline designing & construction

certificate.

Ruiding covers a building area of over 250,000 square meters and has nearly

300 professional and technical staffs. We have completed over 500

engineering projects, spread across various domestic and

international industries, with a significant market share in the

petrochemical industry.

Faq:

1. What is the company's main business?

Focus on the R&D, design, production, installation and

commissioning of industrial three wastes (waste gas/waste

liquid/solid waste) incineration treatment equipment and special

boilers, and provide supporting equipment (such as heat exchangers,

sludge dryers, etc.) .

2. Do you have industry qualification certification?

The company has now passed the quality, environment, occupational

health, and occupational hygiene and safety management system

certifications, and has the second-level qualification for

environmental protection engineering contracting, Class B special

environmental engineering design, Class A boiler manufacturing

qualification, Class A boiler installation, inspection and

maintenance certificate, A2 pressure vessel design and

manufacturing certificate, GC1, GC2 pressure pipeline design and

installation certificate, and Class A environmental pollution

control (waste, waste gas, waste liquid) qualification certificate.

3. What are the core products?

(1) Waste gas incinerator:

Regenerative thermal oxidation furnace (RTO), regenerative

catalytic oxidation furnace (RC0), catalytic oxidation furnace

(C0), high temperature thermal incinerator (T0), catalytic

denitrification furnace (SCR)

(2) Waste liquid incinerator:

Organic waste liquid incinerator, salt-containing waste liquid

incinerator, heavy component residue incinerator

(3) Solid incinerator:

Combined rotary kiln incinerator, gas-controlled pyrolysis

incinerator, fluidized bed incinerator, step-type incinerator

(4) A-level boiler:

Modular waste heat boiler, tunnel waste heat boiler, furnace-boiler

integrated incineration boiler, large cavity membrane wall boiler,

fire tube boiler

(5) Plate heat exchanger:

Fully welded pressure plate heat exchanger, high-efficiency vortex

tube heat exchanger, high-efficiency spiral tube heat exchanger

(6) Incineration auxiliary machine:

Sludge dryer, customized burner, solid waste crusher, VOC catalyst

4. In what aspects are the technical advantages reflected? Have you

ever had experience in cross-border cooperation?

We have 29 patented technologies, covering the fields of

incinerator structure optimization, heat recovery, etc. The company

has a first-class design team in China, which has mastered the

incinerator technology and is familiar with the operation of

incinerators. The designers have a solid theoretical foundation and

rich design and practical experience. During the design process,

they combine the operation of advanced devices at home and abroad

to carry out process and structural design. The design response is

fast, and the plan can be modified in time according to the buyer's

requirements, and optimization suggestions can be made according to

the buyer's data and processes.

5. What does the service scope include?

We provide full-process services from project consultation, scheme

design, equipment manufacturing to installation and commissioning,

and support pressure pipeline and boiler renovation.

6. Are there any successful cases for reference?

It has served multiple industries including petroleum, chemical,

pharmaceutical, and solid waste disposal. Typical cases include

organic waste gas RTO system, chemical waste liquid incineration

project, etc.

7. How to obtain cooperation or quotation?

You can submit your needs through the official website online form,

or contact directly:

Tel: +86 15606162805 ; +86 0510-87418884

Email: ruiding@rdee.com.cn

Address: Xinzhuang Industrial Concentration Zone, Yixing City,

Jiangsu Province, China.

8. Is there any international business cooperation?

Holding the independent import and export rights, we can provide

equipment export and technical solution customization services for

overseas customers.